Engineering In The Blind

A Unique Human View Of Engineering Into The Unknown

Los Angeles, CA USA

By Charles White

(Retired Deputy Chief Knowledge Officer, NASA Jet Propulsion Laboratory)

Introduction: Defining "Engineering In The Blind"

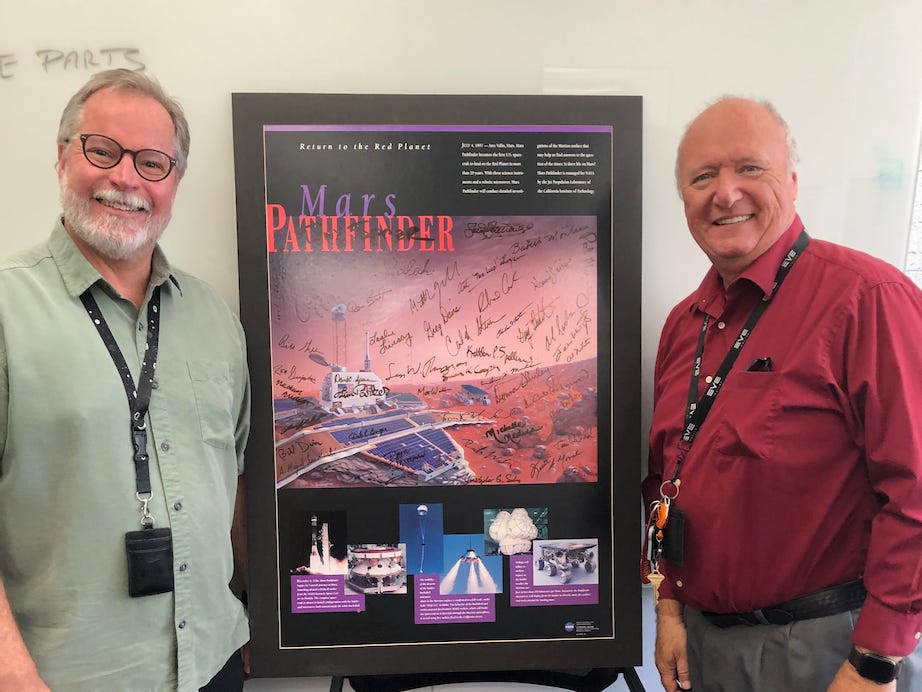

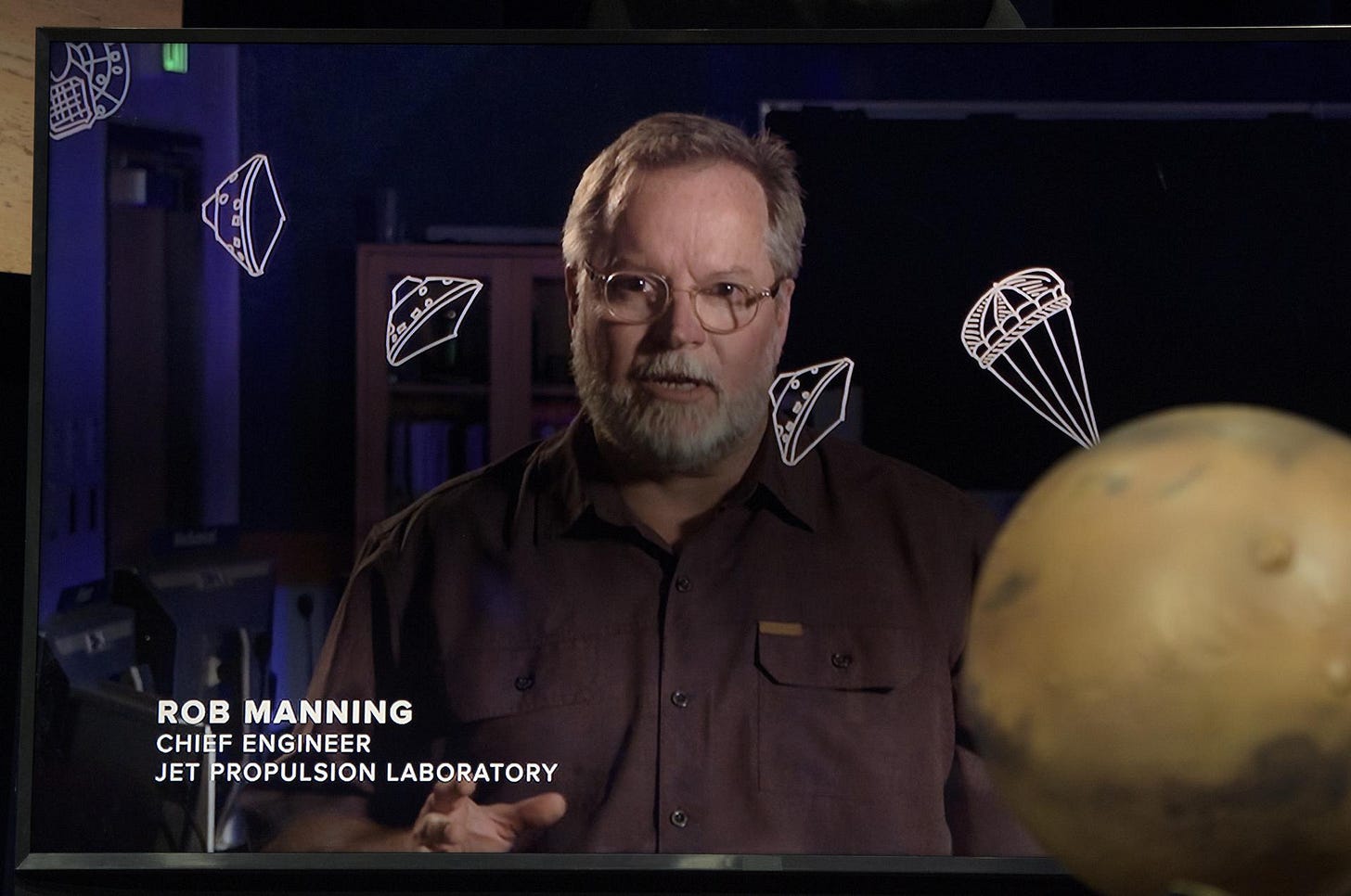

The air in the JPL conference room crackled with a unique blend of exhaustion, elation, and profound relief. It was 10 A.M., February 23, 2021, just five days after the Mars Perseverance rover had executed a flawless landing, captivating the world. Around the table sat the Chief Engineers of JPL's technical divisions, gathered for the weekly Engineering Board meeting – the 'JEB' – led by the then Chief Engineer, Rob Manning. I took my seat. These were the very people who had orchestrated the intricate dance of engineering that resulted in the stunning images and data already streaming back from the Red Planet.

My own position at that table was slightly different. As the Deputy Chief Knowledge Officer, my focus wasn't primarily on designing the hardware itself, but on listening – listening for the hard-won knowledge, the potential engineering lessons learned that needed to be captured from such complex undertakings. With a formal background in Human Behavioral Sciences, I also kept an ear tuned to the human side of engineering, recognizing that engineers, being human, inevitably shape their creations in ways that extend beyond pure technical specifications – though that's perhaps a topic for another article.

On this particular day, the initial roundtable discussion, steered by Rob, was naturally a chorus of congratulations and mutual appreciation. Engineers like Howard Eisen spoke of the immense satisfaction in seeing years of painstaking design, analysis, building, testing, and simulation culminate in success. The complex ecosystem of machines – the cruise stage that navigated the void, the heat shield, the parachute, the sky crane performing its unprecedented maneuver, and the rover itself – had all performed exactly as envisioned across hundreds of millions of miles.

When my turn came, Rob looked my way. I offered my sincere congratulations, but framed it through a different lens. "The world," I stated, "saw the incredible results of what each of you, my colleagues, created in the blind."

A ripple of curiosity went through the room. "In the blind?" Rob asked, clearly intrigued. He, like the other seasoned chief engineers present, hadn't encountered the term before in this context. I explained that it was a concept I'd been developing for some years, my way of articulating a fundamental truth about how we undertake these extraordinary projects: Engineering In The Blind.

That meeting, that moment of shared success viewed through this particular perspective, crystallized my resolve. While Perseverance began its ambitious mission on Mars, exploring Jezero Crater, my own work began in earnest: to fully develop and articulate this vision. Now, years removed from that pivotal JEB meeting and having concluded my 37-year journey at JPL, the time is right to fully explore this idea. This article delves into 'Engineering In The Blind' – the essential, often unseen, process of conceiving, designing, building, and operating complex systems that engineers cannot directly observe or interact with during their most critical phases, relying instead on foresight, rigorous validation, and a profound trust in their own unseen work.

Act 2 - The Unseen Blueprint:

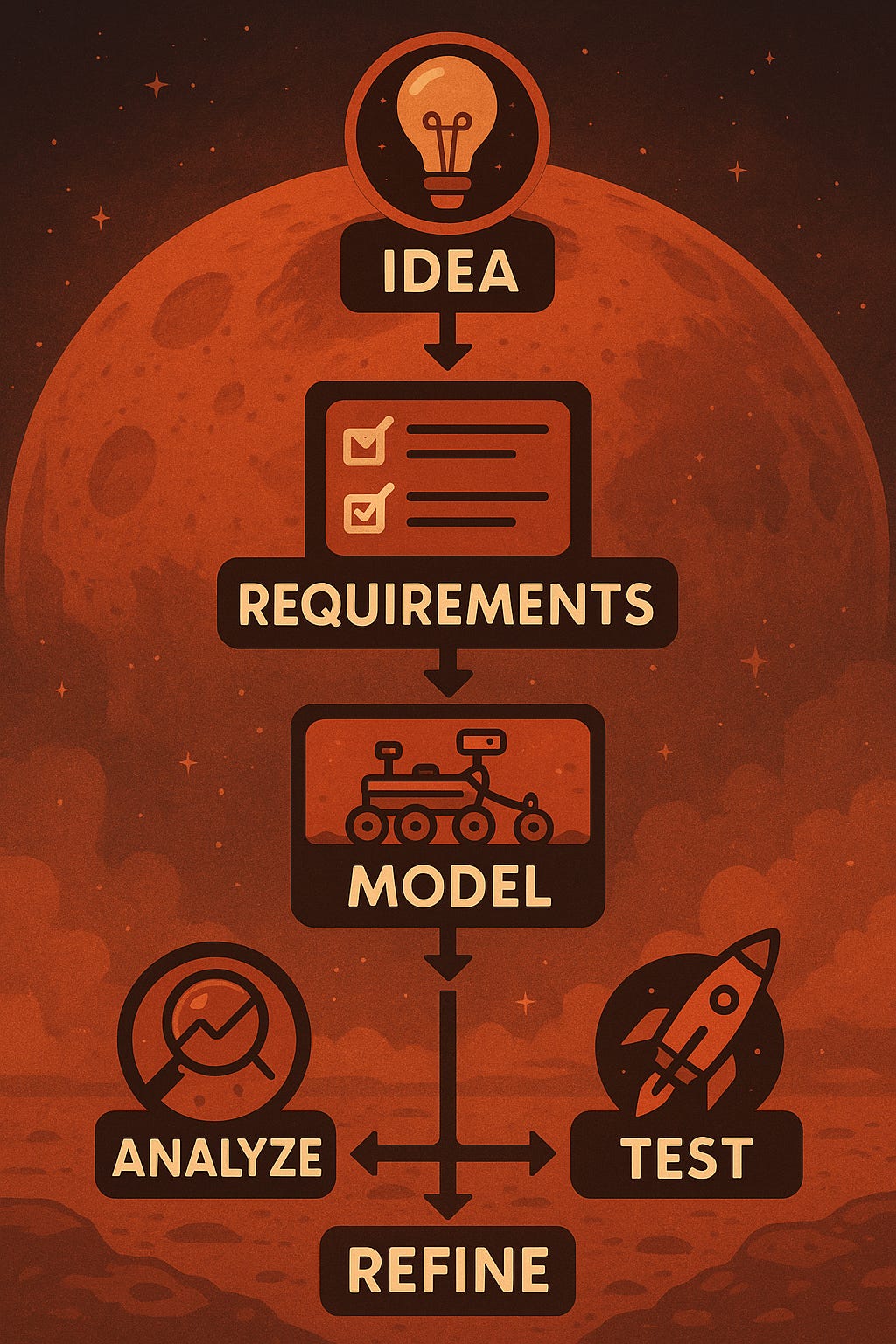

From Mind to Machine

Having introduced the concept of "Engineering In The Blind" through the lens of the Perseverance rover's triumphant arrival, let's delve deeper into the first critical stage of this process: the creation of the unseen blueprint, the journey from pure thought to a tangible, validated design.

Long before a single piece of flight hardware is meticulously machined or assembled, long before the controlled thunder of a launch vehicle splits the sky, the spacecraft – whether it's a Mars rover, an orbiter heading to Jupiter, or a probe destined for the outer solar system – exists only in the collective intellect and digital workspaces of the engineering team. This is perhaps the purest, most foundational form of "Engineering In The Blind."

It begins with the 'why' – the scientific questions or exploration goals driving the mission. "Can we find signs of past habitable environments on Mars?" "What powers Jupiter's intense magnetic field?" "What is the composition of this asteroid?" These ambitious objectives must first be painstakingly translated into the precise, unforgiving language of engineering: requirements.

These requirements form the bedrock upon which the entire structure is built. A sensitive scientific instrument must survive the violent vibrations of launch and then operate flawlessly within specific, often extreme, temperature ranges. A structural element must possess a certain stiffness-to-mass ratio. A communications system must reliably transmit data across unimaginable distances. A rover wheel must withstand the impact of landing and traverse potentially unknown terrain for years. Crucially, many of these requirements are established based on imperfect knowledge of the very environment the machine will eventually inhabit. Mars isn't fully mapped; the deep space radiation environment has uncertainties; the exact texture of a landing site is only known within probabilities.

How do engineers bridge this chasm between abstract need and functional design when the object itself doesn't exist and its destination is a realm of calculated probabilities rather than certainties? They employ powerful tools of abstraction, prediction, and meticulous digital craftsmanship.

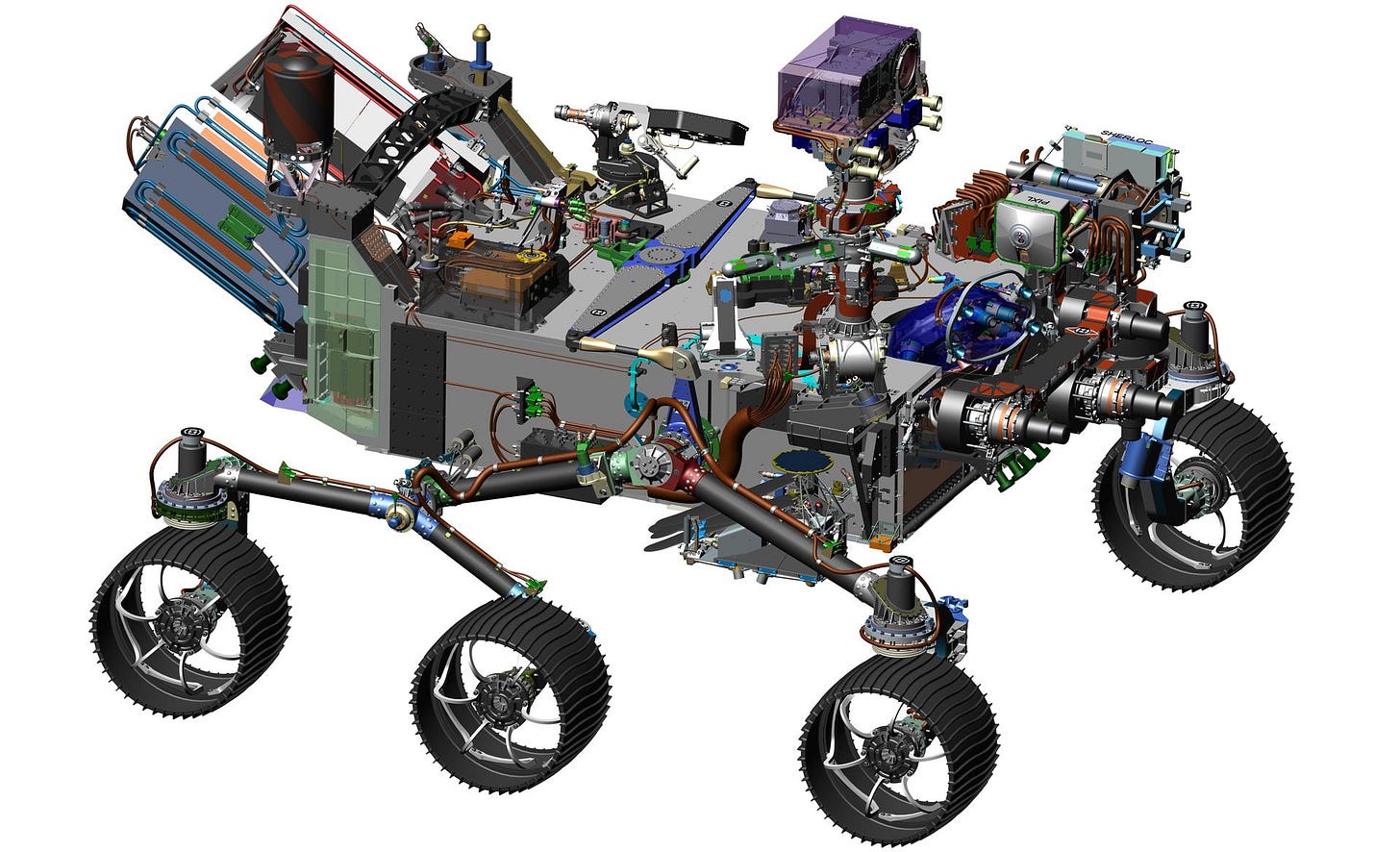

In the modern era, this "unseen blueprint" takes life within sophisticated Computer-Aided Design (CAD) software. Engineers construct intricate, three-dimensional digital models of every component, subsystem, and their complex interfaces. These "digital twins" become the subjects of intense scrutiny through Computer-Aided Engineering (CAE) tools. Finite Element Analysis (FEA) software simulates the stresses and strains on structures under launch loads or landing impacts. Computational Fluid Dynamics (CFD) models predict the searing heat and aerodynamic forces of atmospheric entry. Thermal modeling simulates the spacecraft's ability to maintain acceptable temperatures, balancing the deep cold of space against the heat generated by its own electronics or absorbed from the sun.

Engineers virtually "fly" the mission countless times in simulation, testing guidance algorithms, simulating deployment sequences for solar panels or antennas, and verifying communication links. They are "seeing" the design perform, but only through the lens of the model, the simulation, the algorithm.

And herein lies the profound "blindness" of this stage: these models, regardless of their complexity and fidelity, remain representations of reality, not reality itself. They are constructed upon mathematical equations, physical laws, material property data, and assumptions about environments that may hold surprises. Critical design decisions – the selection of a specific titanium alloy for a landing leg, the precise curvature of a heat shield, the intricate logic embedded within flight software – are made based on the predicted outcomes within these digital realms. The engineers, the entire team, must place immense trust in the predictive power of their analyses, trusting that these meticulously crafted digital phantoms accurately foreshadow the behavior of the real hardware in its future, unseen environment.

This demanding phase isn't solely a digital exercise, of course. It involves intense human collaboration: design reviews where engineers rigorously challenge each other's assumptions, debates over competing design approaches, and countless hours dedicated to refining drawings and analysis results. It requires profound creativity to innovate solutions and unwavering discipline to track interfaces and manage complexity. Physical prototypes of components or subsystems may be built and subjected to tests in specialized facilities – vacuum chambers, vibration tables, thermal cycling ovens – that mimic aspects of the flight environment. But even these tests are proxies, often unable to replicate the combined effects of radiation, thermal stress, vacuum, and dynamic loads that the actual flight hardware will endure, alone and unseen.

This entire monumental effort – translating abstract goals into concrete requirements, requirements into detailed digital models, models into predictive analyses, and analyses into validated design choices – unfolds before the first piece of flight-qualified metal is cut or the first line of mission code is finalized. It is an act of profound intellectual creation and disciplined foresight, performed entirely "in the blind," laying the indispensable foundation upon which the mission's entire fate will ultimately depend.

Act 3 - The Voyage:

Autonomous Systems in the Void

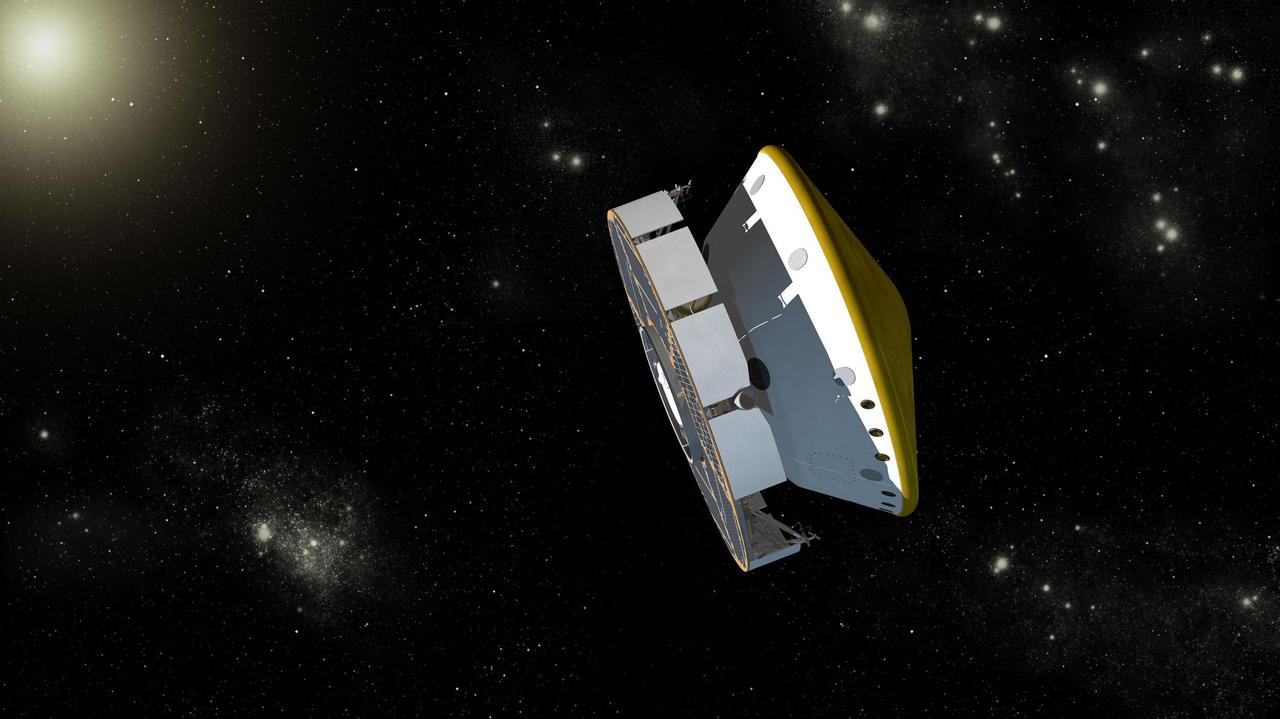

With the "unseen blueprint" meticulously validated through countless hours of analysis, simulation, and ground testing, the moment arrives when the abstract design becomes hardened reality. The spacecraft is built, integrated, and finally launched. As it separates from its launch vehicle and begins its long journey towards its destination, it enters the second critical phase of "Engineering In The Blind": the solitary voyage through the void.

Space is defined by its vastness. Journeys to Mars take months; trips to the outer planets take years. Distances swell to hundreds of millions, even billions, of miles. This isn't just a measure of space, but also of time. Radio signals, traveling at the speed of light, can take minutes (for Mars) to hours (for Jupiter, Saturn, and beyond) to cross the gulf between the spacecraft and Earth. Real-time control, the kind we experience when driving a car or even remotely piloting a drone near Earth, is simply impossible. There is no joystick, no immediate feedback.

This inherent communication delay dictates the absolute necessity for autonomy. The spacecraft must be engineered to be largely self-sufficient, a robotic explorer capable of managing its own intricate systems far from human intervention. It must keep itself correctly oriented in space, often using stars as navigation references. It needs to manage its power resources, charging batteries from solar panels or drawing from nuclear sources. It has to maintain its internal temperature within survivable limits, activating heaters or radiators as needed. It must execute pre-programmed sequences for course corrections or system checkouts.

How, then, do engineers maintain contact and oversight? Not by "seeing," but by "listening" and carefully "speaking." The spacecraft transmits telemetry – streams of data containing vital health information, status reports from various subsystems, and readings from sensors. Back on Earth, flight controllers in mission control centers, often working around the clock, meticulously analyze this delayed data. They are like doctors monitoring a patient's vital signs from afar, looking for subtle trends or deviations that might indicate a problem.

When adjustments are needed – a trajectory correction maneuver (TCM) to refine the path, a command to power on an instrument for a health check – the instructions are carefully formulated, packaged, and transmitted as commands. These commands travel across the vast distance, execute aboard the spacecraft (the engineers hope and trust), and only much later does telemetry arrive confirming the action was completed successfully, or revealing an unexpected issue. Every command sequence sent is an act of calculated faith, projecting human intent across space and time into an unseen, autonomous machine.

Perhaps the most critical element enabling this "blind" voyage is the onboard fault detection and correction system, often called "fault protection." This sophisticated software acts as the spacecraft's immune system and reflexes. It constantly monitors the health and performance of critical components. If it detects an anomaly – a computer glitch, a sensor providing anomalous readings, the spacecraft unexpectedly tumbling – it must autonomously diagnose the issue (to the best of its ability) and take pre-programmed corrective actions. This might involve switching to backup hardware, resetting a computer, aborting a sequence, or putting the spacecraft into a "safe mode" – a stable configuration with essential systems on, awaiting further instructions from Earth. This autonomous guardian is paramount, because when trouble strikes millions of miles away, there's no time for controllers on Earth to react before potential disaster unfolds.

For months or years, the spacecraft sails silently through the black, executing its programming, guarded by its fault protection, while the team on Earth watches the delayed heartbeat of telemetry. It's a testament to the robustness of the design and the thoroughness of the testing performed back on Earth, all carried out in anticipation of this long, unseen, autonomous journey.

This cruise phase embodies "Engineering In The Blind" not as a lack of existence, but as a lack of presence. The machine is real, functional, and incredibly distant, operating beyond the reach of immediate human senses or control, entirely dependent on the foresight embedded in its design and software.

Act 4 - The Crucible:

7 Minutes of Terror and the Blind Trust in Design

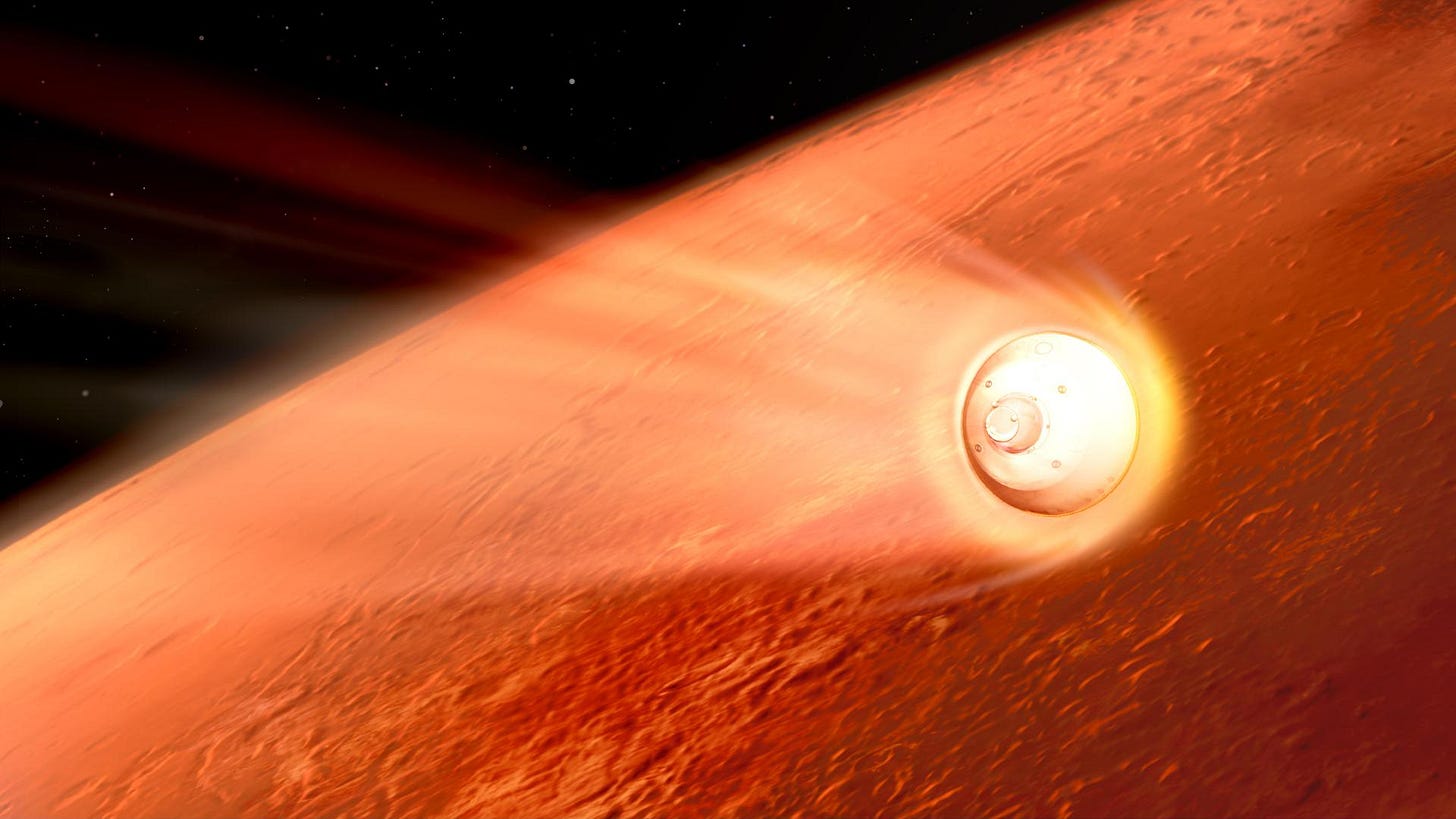

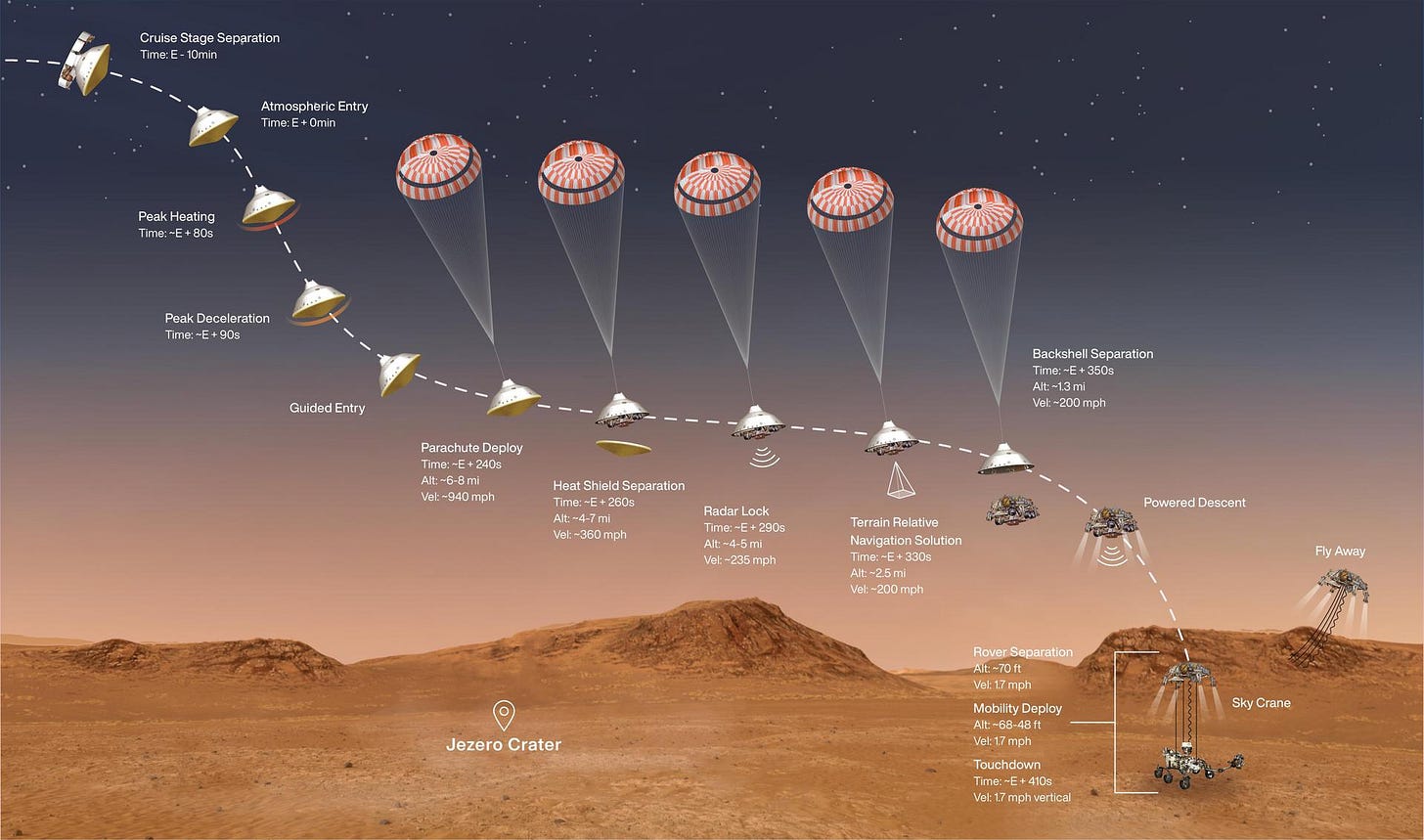

After months or even years sailing silently through the vast, empty ocean of space, sustained by its intricate autonomous systems and watched over by distant engineers interpreting its delayed electronic whispers, the spacecraft finally arrives at the doorstep of its destination. The long cruise, a marathon of calculated navigation and 'blind' endurance, abruptly gives way to the ultimate sprint – the most intense, complex, and perilous phase of the entire mission: Entry, Descent, and Landing (EDL). For missions targeting Mars, this phase has earned a chillingly accurate and evocative nickname: the "7 Minutes of Terror."

This moniker reflects the excruciating reality faced by the mission team anxiously gathered back on Earth. From the moment the spacecraft encounters the first tendrils of the Martian atmosphere to the moment it (hopefully) confirms a safe touchdown on the surface, roughly seven minutes elapse. But due to the inescapable light-time delay – the time it takes signals to travel between Mars and Earth – the entire sequence unfolds autonomously, irrevocably, millions of miles away before the ground team can even confirm it has begun. By the time engineers receive the signal indicating atmospheric entry, the spacecraft has, in reality, either already landed successfully or tragically met its end on the Martian plains.

There is no opportunity for real-time intervention. No joystick, no "undo" button, no last-minute commands can be sent across the void to correct an unforeseen problem. Success or failure hinges entirely, terrifyingly, on the meticulous engineering performed years earlier, the inherent robustness of the design, the flawless execution of hundreds of pre-programmed commands and actions executed by the onboard computers, and the fidelity of the models used to predict the harsh environment. EDL is the ultimate, high-stakes demonstration of "Engineering In The Blind."

The ordeal begins at blistering speed. The spacecraft, encased within its protective aeroshell and heat shield, slams into the thin upper atmosphere at hypersonic velocities, often exceeding 12,000 miles per hour. Atmospheric friction instantly generates unimaginable heat, enveloping the entry vehicle in a shroud of incandescent plasma hotter than the surface of the sun. The heat shield – its specific curvature, thickness, and ablative material composition meticulously designed based on complex computational fluid dynamics and thermal models created entirely "in the blind" – must perform flawlessly, absorbing and dissipating this catastrophic energy surge to protect the precious scientific payload nestled within.

As the searing passage through the upper atmosphere rapidly decelerates the vehicle, a perfectly choreographed cascade of events must unfold with split-second accuracy. At a precisely calculated altitude and velocity, often while the vehicle is still traveling faster than the speed of sound, a mortar fires to deploy a massive parachute. This parachute, perhaps the largest supersonic parachute ever built and tested in specialized facilities on Earth that attempt to simulate the unique Martian atmospheric conditions, must inflate evenly and withstand the tremendous aerodynamic forces. Shortly thereafter, the heat shield, having served its critical purpose, is jettisoned using pyrotechnic separation bolts, falling away to expose the lander's critical radar system. This radar immediately begins actively pinging the rapidly approaching, unseen ground below to determine the spacecraft's precise altitude and descent velocity – vital data needed for the final stages of landing.

The parachute alone cannot slow the spacecraft sufficiently for a soft landing in Mars' tenuous atmosphere. The final, powered phase of descent begins. The backshell and parachute are cut away. For heavier landers like Curiosity and Perseverance, a cluster of powerful retrorockets integrated into a descent stage ignites, actively steering and decelerating the vehicle. This system must throttle its engines precisely, responding in real-time to the radar's measurements of the unseen terrain below. Then comes the audacious and uniquely JPL "sky crane" maneuver: the descent stage hovers on its rocket plumes a safe distance above the ground while lowering the massive rover beneath it on a set of strong cables, or bridles.

The final moments are perhaps the most critical. The rover's landing gear must deploy correctly. The wheels make contact with the Martian surface – touchdown. Even the engineered stiffness and design of those aluminum rover wheels plays a crucial role, specified "blindly" years earlier to help absorb the landing impact loads effectively without compromising the stringent mass constraints imposed by the mission. The instant the onboard computer detects touchdown through sensors in the wheels or landing gear, it must command pyrotechnic charges to fire immediately, severing the bridle and allowing the sky crane descent stage to fly away and intentionally crash-land at a safe distance. If any single one of these complex, interdependent steps fails – if the parachute rips, the radar falters, the engines misfire, the bridle doesn't cut – the mission is likely lost.

Back in mission control, the team watches the telemetry displays, but the data arriving confirms events that are already history, millions of miles away. They might receive confirmation of successful heat shield separation minutes after it actually occurred. They "hear" the parachute deploy long after the fact. The final moments leading up to the expected touchdown are often marked by a tense, almost unbearable silence, punctuated only by the calm, procedural callouts of the flight director relaying the delayed data points. It is a shared, agonizing vulnerability, where the most brilliant and dedicated engineers on Earth can only watch, wait, and hope, placing their complete trust in the integrity of the work they completed "in the blind."

The arrival of that first cohesive signal, or the first relayed status tone from the surface, confirming survival – often resulting in the iconic call "Touchdown confirmed!" – unleashes an explosion of raw emotion: relief, joy, exhaustion, and profound accomplishment. It is the ultimate vindication of the years of design, analysis, simulation, testing, and unwavering foresight. It is the moment the intense "blindness" of EDL finally yields to the first glimpse of success, proving that the immense challenge of engineering for the unseen and the unknown can indeed be met.

Act 5 - The Revelation:

When the Blind See

The excruciating tension of the "7 Minutes of Terror," where engineers could only trust in their past work and wait helplessly as physics unfolded millions of miles away, finally breaks. It shatters not with a sudden visual, but often with the faintest of whispers across the interplanetary void – the confirmation that the "blind" gamble has paid off.

It might be the detection of a simple carrier signal, a specific radio tone transmitted by the newly landed spacecraft, picked up by orbiting assets or the giant antennas of the Deep Space Network (DSN) back on Earth. Or it could be the first small packet of basic engineering telemetry, confirming that the lander is stable, powered, and "alive" on the surface. This first signal, however rudimentary, is electrifying. It's the first tangible proof that the intricate chain of events, designed and executed "in the blind," has held together. The silence is broken; the unseen machine has announced its survival.

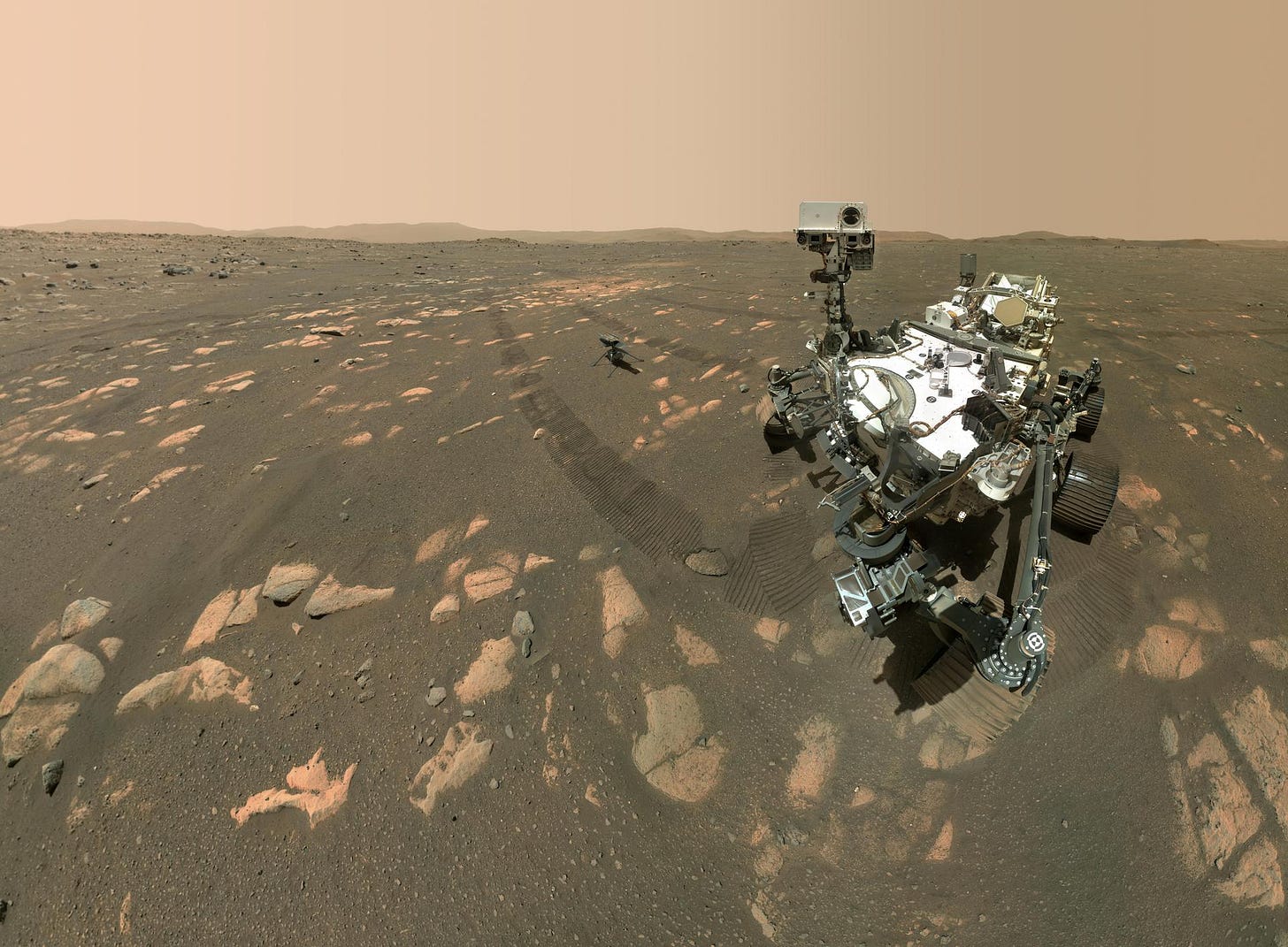

Soon after, often within minutes or hours, come the images that truly bridge the distance and pierce the veil of "blindness." These might be low-resolution views from hazard avoidance cameras (hazcams), initially protected by lens covers, showing the immediate surroundings – the wheels firmly planted in alien soil, the landscape stretching out towards the horizon. While engineers have "seen" Mars through the eyes of previous missions, seeing this specific place, this machine safely arrived, is a profound revelation. For the team, and soon for the entire world, these first pictures transform the abstract destination into a real place and the culmination of their "blind" engineering into a tangible presence.

Concurrent with the first images, more detailed engineering telemetry flows back. Temperatures are checked, power levels assessed, communication link quality measured, instrument health confirmed. This data provides the crucial validation: Did the landing system perform as simulated? Did critical components survive the shock and vibration? Did the power system come online as expected? This flood of information confirms whether the assumptions made, the materials chosen, the algorithms coded – all decided "in the blind" – were correct. It’s the engineering equivalent of a doctor receiving the first definitive vital signs after a critical procedure.

This arrival of data marks a fundamental shift. The era of operating purely "in the blind" gives way to an era of remote observation and control. While engineers still can't physically touch or see the rover or orbiter, they now have eyes and sensors on location. They can see the terrain ahead, analyze the rocks, measure the atmosphere. Operations transition from relying solely on predictive models and pre-programmed sequences to making decisions based on actual, observed conditions relayed back from the spacecraft. The "blindness" is not entirely gone – there's still the light-time delay, and unforeseen issues can arise – but the engineers are no longer designing and flying into a complete unknown.

This "revelation" is the ultimate payoff for the years, sometimes decades, of meticulous work performed under the constraints of "Engineering In The Blind." It validates the rigor of the design process, the thoroughness of the testing, and the incredible foresight required. But touchdown and confirmation are not an end point. They are the triumphant beginning of the next phase: the scientific mission, the exploration, the discoveries – all made possible because engineers dared to design, build, and fly extraordinarily complex machines through the vast, unseen reaches of space.

Act 6 - Learning from the Darkness:

Lessons in Blind Engineering

The euphoria following a successful touchdown, the profound 'revelation' when signals and images finally pierce the darkness after millions of miles and minutes of terror, is not just a moment of mission triumph. For an organization like NASA's Jet Propulsion Laboratory, perpetually operating at the edge of possibility, this culmination is also a critical inflection point – a prime opportunity for reflection and, most importantly, for learning. The crucial question becomes: How can this entire experience, whether a textbook success or one marked by unexpected challenges navigated 'in the blind,' sharpen the foresight needed for the next generation of missions destined for the unknown?

When engineers design intricate systems that must execute complex, unobserved sequences autonomously, far from human reach, the traditional feedback loops of design are stretched thin, almost to the breaking point. Unlike designing a terrestrial vehicle, where engineers can observe countless prototypes and production models operating in their intended environments, deep space missions offer only fleeting glimpses during ground testing and remote, delayed data streams afterward. This inherent limitation makes the systematic capture, rigorous analysis, and effective dissemination of lessons learned absolutely paramount. It is the organization's primary mechanism for illuminating future paths, reducing the inherent 'blind spots,' and iteratively improving the ability to engineer successfully for unseen conditions.

This is precisely where roles like the one I held at JPL as Deputy Chief Knowledge Officer and Lessons Learned Investigator become functionally vital. Capturing this advanced knowledge from these intensely focused engineers, however, is an endemic challenge. It's nearly impossible to expect engineers to meticulously document their 'blind' design rationale or real-time troubleshooting insights while simultaneously immersed in the demanding tasks of creation and problem-solving. Even after the fact, memories can fade quickly, especially in the bright light of success. As a knowledge worker, I would often have to proactively inject myself into the process – observing meetings, documenting key decisions or anomalies witnessed – and then seek review and validation from the engineers later, navigating the persistent challenge of their limited time. (Though the specific hurdles and techniques of capturing lessons learned are rich feed for another article entirely).

Analyzing a mission's performance through the explicit framework of "Engineering In The Blind" provides a uniquely powerful diagnostic lens. When a system performs flawlessly during the autonomous cruise or the gauntlet of EDL, the pertinent questions are: Which fundamental assumptions made years earlier about the environment or component behavior proved remarkably accurate? Which specific modeling techniques or simulation tools were most predictive of the actual 'blind' performance observed? How did the ground testing regimen successfully validate the design against the unseen realities it ultimately faced? Conversely, when anomalies inevitably occur during these 'blind' operational phases: Where did the predictive models diverge most significantly from the experienced reality? Was the spacecraft confronted by an 'unknown unknown' – a physical phenomenon, environmental factor, or failure mode that simply hadn't been anticipated or modeled? Did a subtle interaction between components manifest only under the combined stresses of the actual mission environment, an interaction missed during ground testing? Was the designed robustness or operational margin insufficient for the specific conditions encountered millions of miles from home?

The hard-won answers to these probing questions continuously feed and enrich JPL's vital institutional memory. This is not merely a passive archive; it is an active, dynamic body of knowledge that directly informs and refines design principles, testing philosophies, simulation standards, critical peer review processes, and operational procedures. A challenging lesson derived from diagnosing an unexpected thermal control issue during the 'blind' cruise phase of one mission, painstakingly pieced together from sparse telemetry, can directly lead to updated thermal design requirements or mandate new, specific environmental tests for the next generation of spacecraft embarking on similar journeys. It represents how the organization collectively learns, adapting its practices to better anticipate the myriad challenges lurking in the darkness of the unknown.

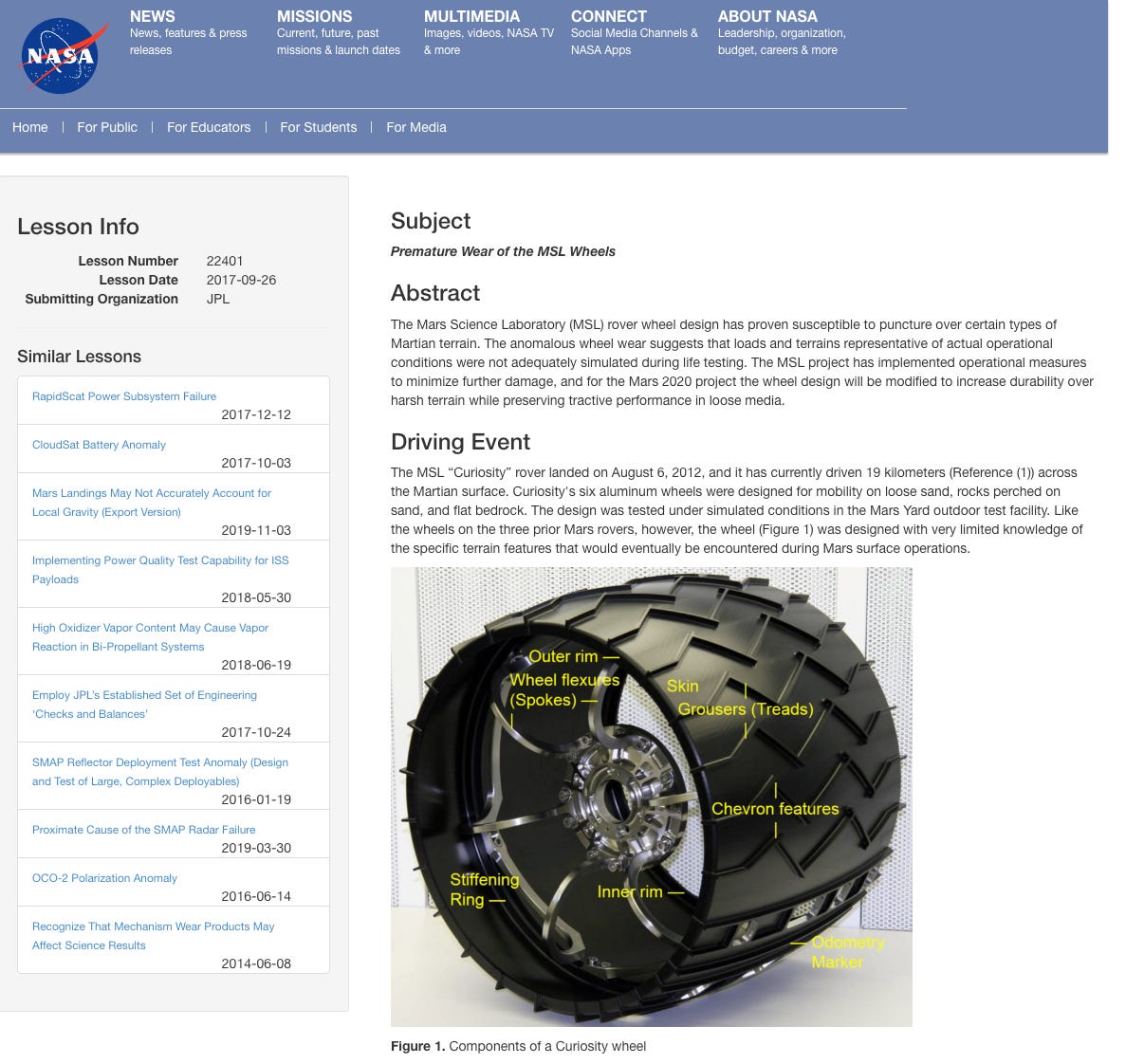

A prime example of this process, documented in NASA Lesson Learned LLIS #22401 which I co-authored with JPL's Chief Knowledge Officer David Oberhettinger, involves the evolution of wheel design for the Mars rovers. During the Mars Science Laboratory mission, the Curiosity rover experienced significantly more wheel wear and damage (punctures and tears) from unexpectedly sharp, embedded rocks than had been predicted based on the models and extensive testing performed 'in the blind' before launch. The specific terrain encountered in Gale Crater simply posed a harsher, more complex challenge than our initial vision and ground simulations had fully captured. This hard-won knowledge, gained by remotely observing the accumulating damage patterns on Curiosity's wheels over years, directly informed crucial design modifications for the subsequent Mars 2020 mission. Consequently, the Perseverance rover explores Jezero Crater with redesigned wheels – incorporating features like increased skin thickness, a modified 'grouser' (tread) shape, and a slightly reduced width and larger diameter – all specifically engineered to better withstand the type of damaging terrain that Curiosity's 'blind' landing inadvertently revealed. This demonstrates exactly how operational experience gained, even from challenges encountered during a mission operating 'in the blind,' illuminates the path forward, allowing engineers to refine subsequent designs and significantly increase robustness for the next inevitable encounter with the unknown.

Link: Premature Wear of the MSL Wheels NASA Lesson Learned

Another subtle but significant lesson, also documented from the MSL mission (LLIS #27901, which I again co-authored), concerned the precision of the final touchdown itself. Post-landing analysis revealed small discrepancies between the predicted and actual touchdown velocities, both vertically and horizontally. These were traced back, in large part, to the 'blind' EDL sequence relying on a gravity model that didn't fully account for fine local variations caused by Mars' specific latitude, altitude, and nearby topography at the landing site. While the landing was successful, these minute velocity errors highlighted how even subtle environmental factors, imperfectly modeled 'in the blind,' can affect high-precision autonomous maneuvers. For future missions demanding even tighter landing tolerances or operating with minimal margins, accounting for such localized gravity effects – refining the 'blind' models or adding new measurements – becomes another crucial piece of learned wisdom derived directly from analyzing performance after a 'blind' operation.

Furthermore, drawing from my background in human behavioral sciences, it was clear that the lessons learned often transcended purely technical domains. One must appreciate the almost mystical ability of these engineers to multitask – holding the complex, evolving 'blind' vision of the final system in their minds while simultaneously navigating a daily gauntlet of timekeeping, mandatory training sessions, numerous meetings (some not directly related to their core task), ongoing technical issues, rigorous testing, and often the responsibility of mentoring other engineers. The sheer pressure and diffusion of focus under which this 'blind' engineering occurs make the eventual success seem even more remarkable. Communication clarity... cognitive biases... team dynamics... these human factors profoundly shape the trajectory of engineering endeavors operating at the edge of visibility. Capturing these socio-technical lessons is equally crucial for enhancing future mission success.

Ultimately, the rigorous practice of investigating and promulgating lessons learned is fundamentally proactive and forward-looking, not merely historical documentation. It is about deliberately taking the rich, often challenging, experiences gleaned from past 'blind' operations – the validated successes, the near-misses, the outright failures – and meticulously transforming them into actionable knowledge. This distilled wisdom empowers the next team of engineers to, metaphorically, stand on the shoulders of those who ventured into the darkness before them, equipped with slightly better 'eyes' and refined tools as they begin, once again, the demanding, essential process of Engineering In The Blind. Seeing the final result – the rover safely on Mars, data streaming back – is the moment the intense, distributed effort undertaken 'in the blind' crystallizes into reality. In mission control and engineering areas, hands are thrown into the air, cheers erupt. It’s an incredible achievement. It worked! And it underscores the critical importance of diligently mining the lessons from that entire demanding journey – from unseen concept to tangible success – to illuminate the path for those who will follow into the next inevitable phase of 'blind' exploration.

Act 7 - Beyond Mars:

The Universality of the Concept

While the journey of a Mars rover provides a dramatic and compelling illustration of "Engineering In The Blind," the core principles and challenges extend far beyond the red dust of Mars or even the vacuum of deep space. This way of thinking – designing, building, and operating complex systems based on predictive models and foresight when direct, real-time observation or intervention is impossible or impractical – resonates across a surprising array of demanding engineering fields.

At its heart, "Engineering In The Blind" is about bridging the gap between human intent and autonomous execution across barriers of distance, time, environment, or complexity.

Consider the realm of deep-sea exploration. Engineers designing Remotely Operated Vehicles (ROVs) or fully Autonomous Underwater Vehicles (AUVs) face immense pressures, corrosive saltwater, near-total darkness, and unpredictable currents. While ROVs may have tethers providing power and data, visibility is often extremely limited. AUVs executing pre-programmed missions operate entirely "blindly" for extended periods, relying on their onboard sensors, navigation algorithms, and fault protection, much like spacecraft. Design decisions about pressure hulls, buoyancy, navigation systems, and sample collection tools are made based on models and simulations, hoping to anticipate the crushing, unseen deep.

Closer to home, the development of autonomous vehicles embodies many aspects of this concept. While self-driving cars are equipped with sophisticated sensors (cameras, lidar, radar) providing real-time data, their control systems operate based on complex internal models of the world, traffic laws, and predictive algorithms about the behavior of other vehicles and pedestrians. The system "sees" data, but interprets and acts upon it based on programming created "in the blind" regarding countless potential scenarios. Handling unexpected "edge cases" – situations not perfectly anticipated by the designers – remains a significant challenge, mirroring the "unknown unknowns" faced in space exploration.

In the digital world, engineers designing large-scale software systems – be it global communication networks, financial trading platforms, or the embedded logic controlling critical infrastructure – often work "in the blind." They design architectures based on anticipated loads and use cases, but the system must then operate autonomously, potentially facing unpredictable user behavior, malicious attacks, or scaling demands far exceeding initial projections. Debugging failures often involves painstakingly analyzing logs and telemetry ("listening" to the system's past state) rather than observing the fault directly as it occurs.

Even within the human body, "Engineering In The Blind" is practiced. Pacemakers, implantable defibrillators, or neural stimulators are designed based on sophisticated physiological models and rigorous bench testing. Once implanted, they must operate reliably and autonomously for years, unseen. Engineers rely on remotely gathered telemetry to monitor performance and battery life, having designed the device "blindly" to withstand the complex, dynamic biological environment and adapt to potential changes in the patient's condition.

Across these diverse fields, common themes emerge: a profound reliance on predictive modeling and simulation; the critical need for robust autonomous operation and fault tolerance; the importance of designing for uncertainty and potential "unknown unknowns"; the necessity of remote monitoring or post-hoc analysis ("listening") rather than direct observation; and the vital role of learning from past performance to inform future designs meant to operate "in the blind." Underpinning all of this is a particular engineering mindset, a perspective perhaps best captured by phrases I often used during my career: "I work over the horizon" and "I live in the future." It reflects the necessity of mentally operating beyond the limits of current observation, constantly needing to "see" and engineer for conditions, interactions, and potential failure modes that may only manifest far away or far ahead in time—aspects that people focused solely on the present-temporal tense don't typically engage with, but which must be anticipated and accounted for in the design conceived today.

"Engineering In The Blind," therefore, is not merely a quirk of space exploration. It is a fundamental paradigm inherent in many of humanity's most ambitious technological endeavors, demanding extraordinary foresight, rigor, and trust in the power of design to conquer the unseen.

The Final Act - Conclusion:

The Foresight of Engineering

Throughout this exploration, the concept of "Engineering In The Blind" has served as our guiding lens – a framework for understanding the extraordinary process of conceiving, designing, building, and operating complex systems through environments where direct human presence and real-time intervention are impossible. From the initial spark of an idea existing only as calculations and lines on a screen, to the heart-stopping silence before confirmation of a safe landing on another world, this inherent "blindness" is a fundamental condition, a defining challenge, of much pioneering engineering.

We have journeyed through the distinct phases of this challenge: the meticulous creation of the "unseen blueprint" relying on the predictive power of models and simulations; the long, solitary voyage across the void where engineers must "listen" rather than see, trusting in robust autonomy; the fiery, unobserved crucible of Entry, Descent, and Landing where success hinges entirely on the integrity of the design executed years prior; and the profound "revelation" when telemetry and images finally confirm that the unseen has been achieved. We've recognized the critical importance of systematically learning from these "blind" operations, embedding hard-won wisdom from both successes and failures into future endeavors. And we've seen how this demanding paradigm, so vividly illustrated by Mars exploration, extends its reach into diverse fields – deep beneath the oceans, within the intricate logic of autonomous vehicles and complex software, and even inside the human body.

"Engineering In The Blind" demands far more than just technical proficiency. It necessitates exceptional foresight – the capacity, as I often articulated it during my career, to "work over the horizon" and "live in the future." It requires engineers to mentally project themselves beyond the present-temporal tense, to anticipate and design for conditions, interactions, and potential failure modes that exist only in prediction or probability, not in current, observable reality. This mindset must be coupled with unwavering rigor in analysis, simulation, verification, and testing – using every available tool to "see" indirectly and build confidence before committing to the unseen. It relies fundamentally on robust design principles, thoughtful redundancy, sophisticated autonomy, and, as we've discussed, a disciplined culture of continuous learning that transforms encounters with the unknown into institutional knowledge.

Ultimately, this endeavor is a profound testament to human ingenuity. It showcases our ability to project our intellect and intent across vast distances and complex challenges, to create reliable proxies for our senses through data and telemetry, and to build machines that can act as extensions of our curiosity in places we cannot yet physically reach. It requires not only brilliance but also immense discipline, collaboration, and a willingness to place calculated trust in the predictive power of our engineering.

Recalling that JEB meeting after the Perseverance landing, where my concept of 'Engineering In The Blind' seemed novel to those brilliant chief engineers, offers a final insight. Perhaps for them, immersed daily in the intricate details and armed with powerful predictive tools, the 'blindness' is less apparent. Their own foresight, their intimate understanding of the design, is so strong that they can, in a sense, vividly 'see' the future successful operation in their mind's eye long before it occurs.

Yet, for those of us watching from the outside, witnessing a rover land flawlessly after its unseen journey and perilous descent remains almost inconceivable, a seemingly superhuman feat.

The truth bridges these perspectives: this extraordinary work is indeed accomplished by us, by humans – just Rob, just Howard, just David, just the dedicated colleague down the hall, and just me – normal people privileged to live and work, day in and day out, within a realm of challenge and discovery that pushes the very boundaries of what seems possible.

The rovers exploring Mars today, the probes venturing toward the distant edges of our solar system, and the countless other complex autonomous systems operating "in the blind" are far more than just technological marvels. They are tangible manifestations of humanity's relentless ambition to push beyond the visible horizon, to comprehend the unknown, and to reliably engineer reality from rigorous foresight. They are the remarkable, hard-won results of engineers daring, and succeeding, to create in the blind.

— Charles White, Space Explorer and just me thinking over the horizon

Postscript: As I Reflect…

As I reflect on the nature of "Engineering In The Blind" and the incredible minds I had the privilege to work alongside at NASA's Jet Propulsion Laboratory, my thoughts turn inevitably to my own path – a journey that began far removed from the rarefied air of interplanetary exploration. My father, a man who didn't finish school before his service took him to Germany, drove a forklift in a warehouse. My mother, who bravely built a new life in America after escaping Germany with him, shared in raising me with diligence and modest means. Their perseverance laid a foundation I could scarcely comprehend at the time.

To have found my way from those humble beginnings to spend 37 years immersed in the unique culture of JPL – a place literally striving to reach other worlds – remains a source of profound wonder and deep gratitude. I walked halls and sat in meetings with engineers and scientists of breathtaking talent, individuals shaping the future with calculations, code, and inspired vision. Though my formal path was different, rooted in the human sciences rather than engineering schematics, I was welcomed into their midst. I was included.

More significantly, I felt trusted – trusted to listen with a different ear, to observe the human dimensions of complex technical challenges, and to help capture and preserve the invaluable, often hard-won, knowledge that fuels the next generation of missions. That trust, extended across disciplines and backgrounds, is perhaps part of the quiet magic that enables teams to undertake and succeed in such audacious 'blind' endeavors.

And the pride... it swells anew within me each time a JPL mission achieves another milestone, appears in the news cycle, or is simply mentioned with admiration in passing conversation. To know that my work, focused on learning, memory, and understanding the very human process of creation and discovery, contributed – even in its own particular way – to that magnificent, unfolding history... it connects me intrinsically and permanently to every successful landing, every distant encounter, every stunning image, every vital piece of scientific data returned from the void.

It allows me, the son of a forklift driver and a resilient immigrant, to look back on nearly four decades dedicated to supporting humanity's reach for the stars and to affirm, with deep humility and quiet conviction: I too, am part of that incredible story.

I am a space explorer. -CW

Bonus Content…

Deep Dive Podcast - Engineering In The Blind

This podcast is based on the Substack article Engineering In The Blind. The podcast goes even deeper than the article about the Mars 2020, Perseverance Rover’s mission.

Please note, Charles White is retired and presently not endorsed, or sponsored by NASA, JPL, Caltech, CCP Games, the First Galactic Empire, the United Federation of Planets, the United States Forest Service, the United States Air Force or Navy, or The Huntington Library Gardens and Museums… but they do like him behind his back.

I remember. Glad to see the post explaining your concept!